Heavy duty Granulator

Category:

Advantage & Benefit

Features

Blades are made of chromium alloy steel with high strength and durability

The distance between the rotary and fixed blades is adjustable

The inner layer of the hopper is made of stainless-steel to reduce noise

Benefit

Multiple protection systems

Operational safety

Low noise

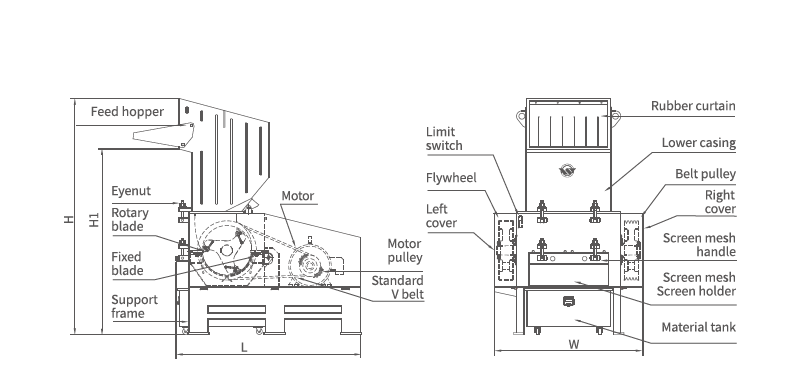

Technical Specifications

| Model |

Crushing Chamber (mm) |

Throughput(kg/h) | Fixed Blade(pcs) | Rotary blade(pcs) |

Power(hp) |

Screen Doening (mm) |

Dimension L x W x H (cm) |

From Feed Hopper to the Ground H1(cm) |

Net Weight (kg) |

|

| KW | HP | |||||||||

| VGY-10HP | 360×260 | 200-400 | 2 | 18 | 7.5 | 10 | 8 | 106×83×144 | 113 | 540 |

| VGY-15HP | 420×280 | 300-500 | 2 | 21 | 11 | 15 | 8 | 127×94×160 | 127 | 795 |

| VGY-20HP | 480×330 | 350-550 | 2 | 24 | 15 | 20 | 8 | 137×101×179 | 141 | 1040 |

| VGY-30HP | 660×350 | 500-800 | 4 | 27 | 22 | 30 | 10 | 157×132×200 | 160 | 1700 |

| VGY-50HP | 720×500 | 800-1200 | 4 | 27 | 37 | 50 | 12 | 187×151×248 | 194 | 2750 |

| Model |

Crushing Chamber (mm) |

Throughput(kg/h) | Fixed Blade(pcs) | Rotary blade(pcs) |

Power(hp) |

Screen Doening (mm) |

Dimension L x W x H (cm) |

From Feed Hopper to the Ground H1(cm) |

Net Weight (kg) |

|

| KW | HP | |||||||||

| VGD-10HP | 360×260 | 170-340 | 2 | 6 | 7.5 | 10 | 8 | 106×83×144 | 113 | 525 |

| VGD-15HP | 420×280 | 255-420 | 2 | 6 | 11 | 15 | 8 | 127×94×160 | 127 | 765 |

| VGD-20HP | 480×330 | 300-460 | 2 | 6 | 15 | 20 | 8 | 137×101×179 | 141 | 980 |

| VGD-30HP | 660×350 | 420-680 | 4 | 9 | 22 | 30 | 10 | 157×132×200 | 160 | 1640 |

| VGD-50HP | 720×500 | 680-1000 | 4 | 9 | 37 | 50 | 12 | 187×151×248 | 194 | 2700 |

Application Scenarios

Bottle embryo (VGD)

Woven Bag (VGD)

Plastic Bucket (VGD)

Rubber Head Material (VGY)

Plastic pipe (VGY)

Plastic rod (VGY)

Previous

Next

Previous

Next

FAQ

How do you turn plastic into granules?

The process involves cutting plastic scraps into small pieces and heating them until they melt. The molten plastic is then passed through a die, which produces cylindrical pellets. These pellets can be reused as raw material in manufacturing plants, thereby reducing raw material costs.

What is a granulator and what type of material is fed into it how is the regrind used?

A granulator is specifically used in plastic processing for size reduce plastic lumps into plastic flakes, resin or regrind. Granulators are used to reduce runners and scrap back to pellet size pieces that blend back in with virgin resins. Granulator is also known as crusher or grinder.

What are granulators used for?

Granulators are essentially rotary grinders that are used to grind scrap parts and melt delivery systems (sprues and runners) into feedstock sized granules for reprocessing. This allows the molder to reduce waste and produce components more cost effectively.

What is a plastic granulator?

A Plastic Granulator is a machine used for breaking down plastic products for Recycling. These machines come in a variety of types for industries and workshops and the various sizes of plastic products.

What is plastic processing machine?

Plastic processing machinery is used to create a variety of products. This machinery is designed to process raw materials and turn them into usable forms.

Online Message