Vertical baler-VB010

VB010

Category:

Advantage & Benefit

Advantage

High revenues for direct marketable bales

Improvement of in-house disposal-logistics

Low frequency transports in-house and external

Benefit

Savings in disposal costs

Saving more time for your core business

Easy to install with no special foundation needed

Technical Specifications

Press force

10T

Cycle Time

30s

Power Supply

380V/50Hz,3 phase

Protection Class

IP55

Application

Cardboard/Textile/Plastic film&bottles

Noise Level

≤80dB

Motor Power

3kw

Feed opening size

810 x 435mm

Bale size

800 x 600 x 800mm

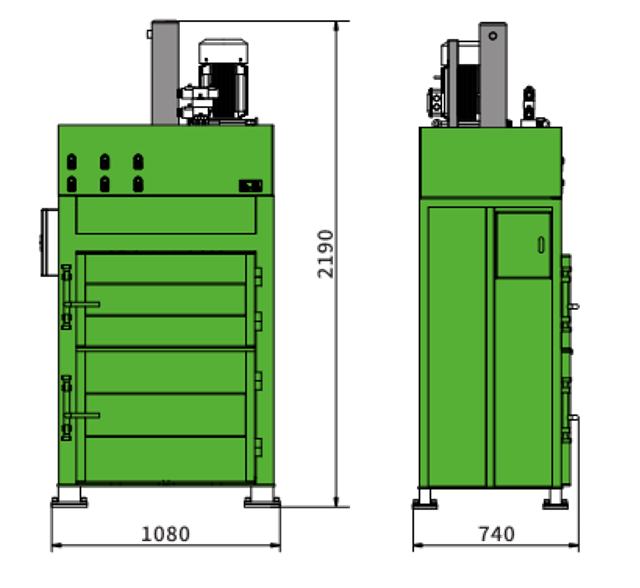

Dimensions

1100 x 750 x 2190mm

Weight

600kg

Application Scenarios

Commumity

Restaurants Hotel

Supermarket Shopping Mall

Commumity

Industry Manufacturing

Hospital

Previous

Next

Previous

Next

FAQ

How often do vertical baler need to maintained?

Different components need to be regularly inpected and maintained, the details of methods and cycles in the user manual to ensure safety operation and extend the life of machine.

What type of hydraulic oil is used for bin compactor and vertical baler?

# 46 anti-wear hydraulic oil.

What are the requirements for power supply for vertical packaging machines?

In domestic use, the electrical system requires AC380V/50HZ/three-phase electricity, and the DMK packaging machine uses aviation plugs, which are safe, reliable, and durable. Projects used abroad need to be customized according to local electrical requirements. For details, please consult professional sales personnel at DMK.

Is the operation of the vertical packaging machine safe?

Due to the compression operation of the packaging machine in a closed sealed compartment and the installation of safety limit switches, the safety during operation is ensured. Of course, operators need to undergo training before they can use the equipment, and regular inspections and maintenance of the equipment also need to be carried out by professional repair technicians. Each Demaike device comes with a detailed product manual to guide users on proper use and maintenance.

How to choose the model of vertical packaging machine?

Vertical packaging machines come in different sizes and models to choose from, depending on the type, quantity, and original size of recyclable materials. In addition, it is necessary to plan the space for placing equipment in advance. You can evaluate and provide the best selection suggestions for you by contacting professional sales personnel at DMC.

How does a vertical packaging machine work?

Manually insert the recyclable materials that need to be compressed into the compression chamber, and compress the materials into tight bundles inside the chamber. After sufficient material is compacted, it is packed into shape with metal or plastic strapping, and then ejected and placed on the transfer tool.

Online Message