vertical baler-VB003

VB003

Category:

Advantage & Benefit

Advantage

Suited for cardboard packaging, paper and plastic film.

The volume reduction of recyclables is by at 80%.

The small baling presses can easily be placed inside low buildings

Benefit

More revenues for direct marketable bales

Save logistics & storage costs

Space saving and cleanliness

Technical Specifications

Press Force

3T

Cycle Time

30s

Power Supply

380V/50Hz,3 phase

Protection Class

IP55

Application

Cardboard/Plastic film

Noise Level

≤75dB

Motor Power

1.5kw

Feed opening size

650 x 450mm

Bale size

650 x 450 x 600mm

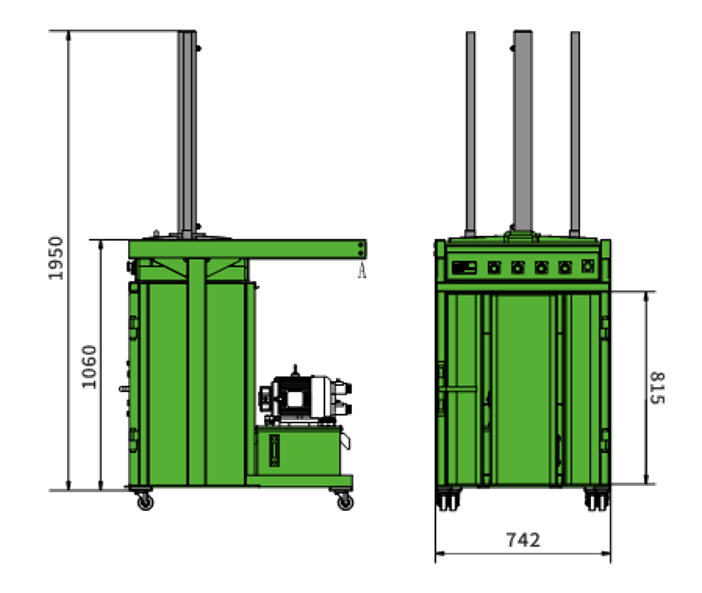

Dimensions

935 x 1015 x 1950m

Weight

450kg

Application Scenarios

Commumity

Restaurants Hotel

Supermarket Shopping Mall

Commumity

Industry Manufacturing

Hospital

Previous

Next

Previous

Next

FAQ

Is loud noise from bin compactor and vertical baler?

The operating noise is in the reasonable range and placed in the work condition without any negative impact.

How often do vertical baler need to maintained?

Different components need to be regularly inpected and maintained, the details of methods and cycles in the user manual to ensure safety operation and extend the life of machine.

What type of hydraulic oil is used for bin compactor and vertical baler?

# 46 anti-wear hydraulic oil.

What is a vertical packaging machine?

It is a device that compresses loose materials such as cardboard, film, or PET bottles into tight bundles for easy storage and transportation. The difference from a horizontal packing machine is that a vertical packing machine compresses materials into packages from the top to the bottom.

How does a vertical packaging machine work?

Manually insert the recyclable materials that need to be compressed into the compression chamber, and compress the materials into tight bundles inside the chamber. After sufficient material is compacted, it is packed into shape with metal or plastic strapping, and then ejected and placed on the transfer tool.

What are the advantages of a vertical packaging machine?

Space saving: significantly reduces the volume of recyclable materials, effectively increasing available space.

Easy to operate: Any person only needs simple guidance to use.

Time saving: Bundled recyclable materials are easier to transport, standardized operations, and save work time.

Optimize disposal management: Compact bundling takes up less storage space and maximizes transportation utilization.

Online Message